Connector Mating System Maintenance

From MCEWiki

Related topics:

► Hardware

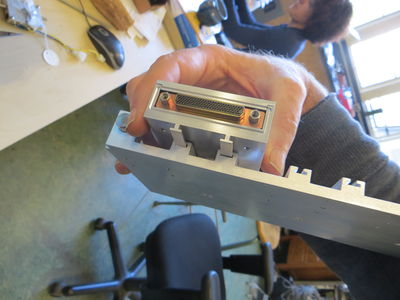

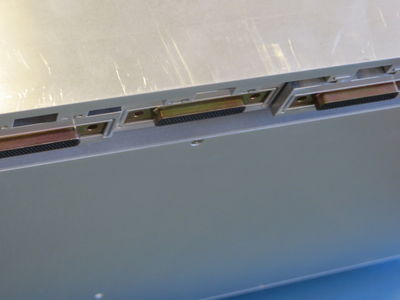

| in a filtered housing sitting on rails. A threaded shaft drives this connector towards or away from the cryostat. | |

| The shaft pushes or pulls the filter/connector box w.r.t. the rest of the electronics. The flex electrical connector connects to the backplane. | |

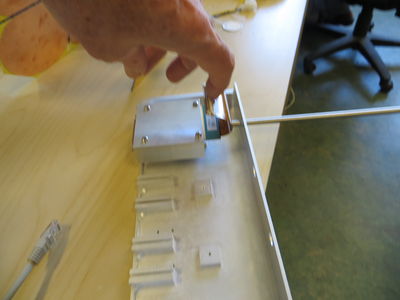

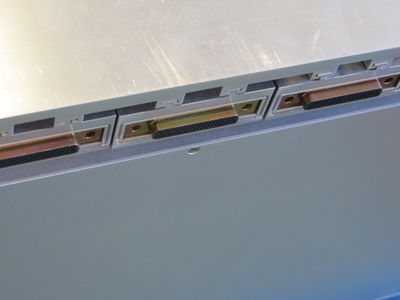

| Inside view of the housing showing a pair of slots for the rails per MDM and the hole for the bolt which keeps each filter/connector box from moving too far once installed. | |

| This close up shows the rails and also the oval slot used to keep the filter from moving too far. | |

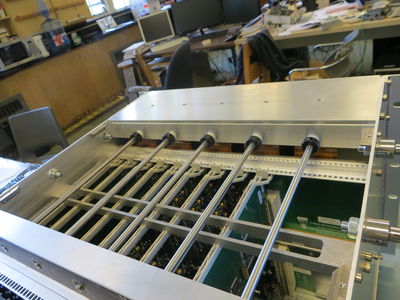

| showing the hex front ends of all the connector mating shafts. Notice that even when well adjusted there may be small differences in how far each shaft end protrudes. | |

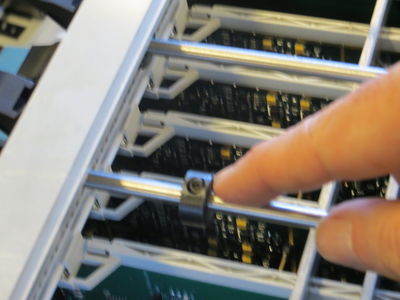

| Looking back towards the front panel from above the MCE, see that each shaft is held from moving out of the front of the box by a black steel split clamp. These clamps rest against the front inside of the MCE. The insertion force for the connectors arise in reaction from these clamps pushing on the front of the MCE top panel. | |

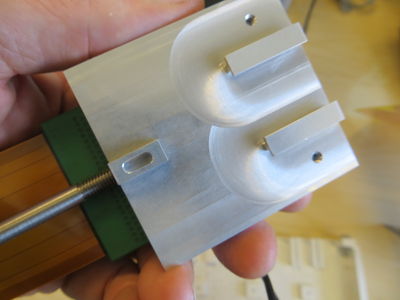

| Looking out towards the cryostat, if one iwas present, from above the MCE, see a set of teflon washers and another set of black split-ring clamps. These clamps keep the shafts from moving towards the cryostat. The force to remove a connector from the cryostat arises in reaction to the force these rear rings apply to the housing. Notice also the bolts which serve ae retaining pins for the filter/connector boxes. | |

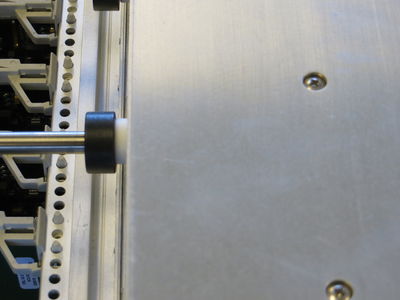

| Pressing the front panel hex heads brings the rear split ring into contact with the teflon washer and the Rear housing. | |

| Pulling on the front of the shaft can open a small gap at the rear before the front split ring come s into tension with the front of the MCE box. A gap of 1mm or so, as seen here, is typical. | |

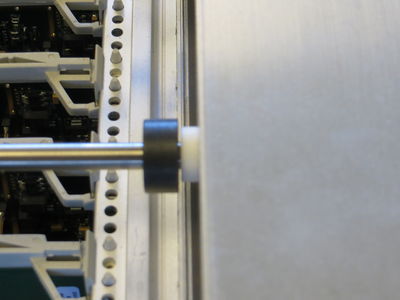

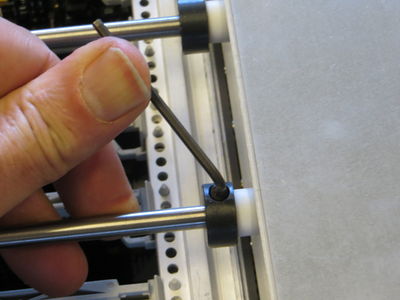

| To remove or re-position a shaft, first loosen the rear split ring. | |

| ..and slide it forwards. | |

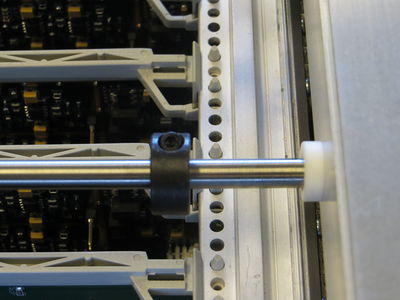

| Then, loosen the front split ring. This might be a bit easier if you turn the shaft a few turns to allow the front ring to come away from the front wall.

Victor, who usually does this assembly and who, modestly, does not claim to do anything difficult, says this step requires a little bit of manual dexterity. | |

| ..and slide it towards the back. | |

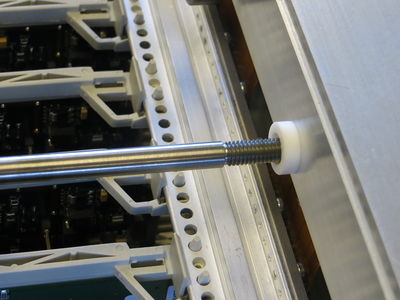

| Now you can unthread the shaft and it becomes free to move forward. | |

| Notice that the shaft threads are LEFT HANDED!! THis is to keep the sense of which way to turn the bolt to tighten the connectors. (You are actually pushing, not pulling.) Remember, the teflon washers and split rings are all still on the shaft. If you are actually removing the shaft try not to drop all the bits down into the cards. | |

| See that the one of these connectors whose shaft has been partly removed, and whose split-ring clamps have been moved is not alligned with the other MDM connectors. | |

| ..so align it by hand. | |

| Thread the shaft into the filter box until you are happy with how the shaft is positioned. | |

| Slide the split ring clamps back where they belong. | |

| ..and tighten them in place. |